Ike siri ike dị n'ebe gburugburu weld ahụ nwere ike inyere aka inyocha ike nke weld ahụ, si otú a na-enyere gị aka ikpebi ma weld ahụ nwere ike achọrọ, yabụ usoro nnwale ike Vickers bụ ụzọ nke na-enyere aka inyocha ịdị mma nke weld ahụ.

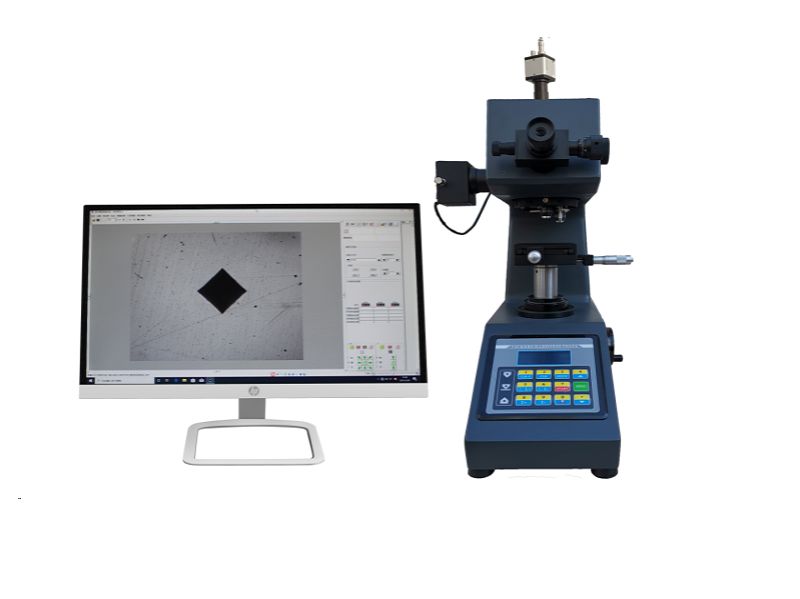

Ihe nnwale ike Vickers nke ụlọ ọrụ Shandong Shancai /Laizhou Laihua Testing Instrument nwere ike ime nnwale ike na akụkụ welded ma ọ bụ ebe welded. Mgbe a na-anwale ike nke ebe welded, a ga-eme nha ọtụtụ isi n'ebe dị anya site na nsọtụ ihe nlele ahụ ma ọ bụ n'elu ebe welded. Mgbe enwetara ntinye ọtụtụ isi, enwere ike ịtụ uru ike site na nha na-aga n'ihu ma nwee ike nweta eserese mgbagọ.

Mgbe ị na-eji ihe nnwale ike Vickers nwalee akụkụ ndị a gbanyere agbakọta, a ga-ahụrịrị ọnọdụ ule ndị a:

1. Nha nha nke ihe nlele ahụ: Tupu anyị anwale ya, anyị na-agweri ihe e ji agwakọta ya ka e wee nwalee ya ka elu ya dị nro, na-enweghị ihe mkpuchi oxide, mgbawa na ntụpọ ndị ọzọ.

2. N'ahịrị etiti nke weld ahụ, were otu ebe n'elu gbagọrọ agbagọ kwa 100 mm maka nnwale.

3. Ịhọrọ ike ule dị iche iche ga-ebute nsonaazụ dị iche iche, yabụ anyị ga-ahọrọ ike ule kwesịrị ekwesị tupu anyị anwale ya.

Ihe nnwale microhardness nwere ihe achọrọ maka imecha elu nke ihe nlele a nwalere, nke kwesịrị ịkwadebe nke ọma dịka ihe nlele metallographic si dị.

Ụkpụrụ nnwale siri ike dị na usoro nnwale siri ike dị kpọmkwem otu ihe ahụ dị na ike siri ike nke Vickers, mana ibu ejiri dị obere karịa ike siri ike nke Vickers dị obere, nke na-adịkarị obere karịa 1000g, ebe ntinye aka na-esi na ya pụta bụ naanị obere micron ole na ole ruo obere micron abụọ, yabụ ule siri ike na-enye ụzọ dị mma maka ịmụ ihe gbasara ọdịdị nke oyi akwa a na-agbagharị agbagharị. A na-ejikarị ya ekpebi ike nke usoro ọ bụla dị n'elu na n'ime oyi akwa a na-agbagharị agbagharị.

A na-ejikarị HV egosipụta akara nke ike microhardness, ụkpụrụ na usoro mkpebi ya yiri usoro ike Vickers. Sistemụ ibu, usoro nha na nkenke indeter nke onye nnwale microhardness na-achọ ihe karịa nke onye nnwale Vickers siri ike dị obere. Ugbu a, a na-ejikarị igwe nnwale microhardness eme ihe n'ọtụtụ ebe dị gịrịgịrị, ebe ọ bụ na ibuli elu nwere ike iru ugboro 400, a na-ejikarị ya eme ihe dị ka igwe microscope dị mfe.

N'oge ojiji, a ga-elebara ibu, micrometer na indenter nke ihe nnwale microhardness anya, nke a ga-enyocha tupu ejiri ya, a ga-ejikwa ngọngọ siri ike maka njirimara zuru oke nke uru ya.

Ihe nnwale siri ike nke microhardness na-etinye ibu ahụ n'ọrụ nnwale ahụ dị ka nke dị nro ma dịkwa otu o kwere mee, na-enweghị mmetụta na mkpọtụ. Iji hụ na nsonaazụ nnwale ahụ ziri ezi, ọ na-adịkarị mkpa ịtụ ọtụtụ ugboro n'akụkụ dị iche iche, wee chọta uru nkezi iji gosipụta uru siri ike nke oyi akwa nnwale permeability ma ọ bụ usoro alloy. Maka oyi akwa infiltration ejiri na okpomọkụ dị elu, enwere ike ịtụ ike ya site na iji ihe nnwale microhardness dị elu.

Oge ozi: Eprel-10-2024