Dịka anyị niile maara, usoro nnwale ike ọ bụla, ma Brinell, Rockwell, Vickers ma ọ bụ onye na-anwale ike Leeb, nwere oke ya ma ọ bụghị ike zuru oke. Maka ọrụ geometric buru ibu, dị arọ na nke na-adịghị agbanwe agbanwe dịka nke egosiri na ihe atụ na-esonụ, ọtụtụ ụzọ nnwale ugbu a na-eji ihe nnwale ike Leeb ebugharị ebugharị iji chịkwaa ike ha.

Usoro nha ike nke Leeb tester nwere ọtụtụ ihe ndị na-emetụta izi ezi nke ike ya: dịka: modulus elastic material, oriri isi bọọlụ, oke iru ala workpiece, radius curvature, omimi oyi akwa siri ike, wdg. Ma e jiri ya tụnyere usoro nha static nke Brinell, Rockwell na Vickers, njehie ahụ buru ibu karịa. Ọ bụrụ na ike ahụ chọrọ izi ezi ka mma, kedu ka anyị ga-esi họrọ onye nnwale siri ike?

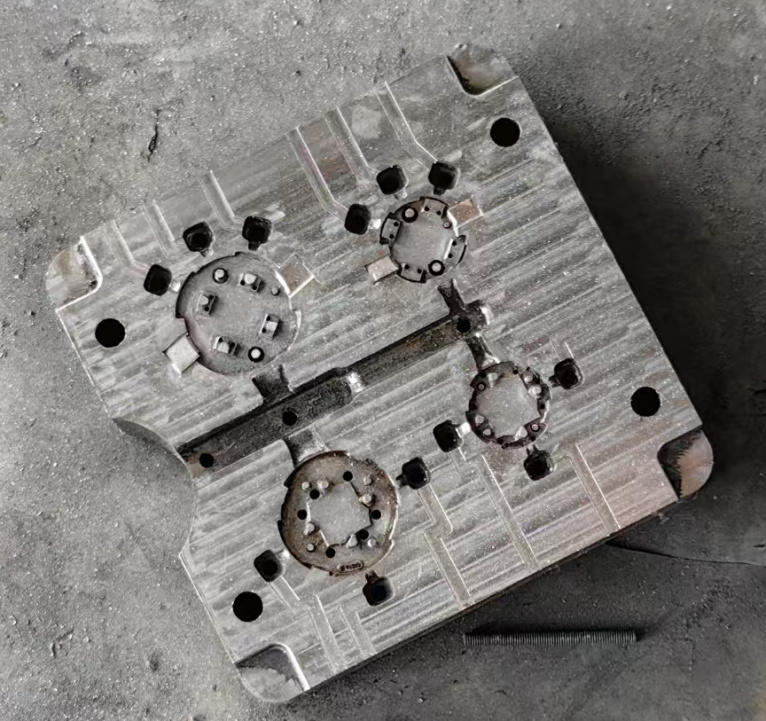

Ụdị ọrụ dị arọ a n'usoro nnwale nnwale ike nkịtị, tupu ibu na ibupụ nnwale nnwale ike, na ibupụ nnwale nnwale ike ga-eweta nnukwu ibu ọrụ n'usoro ọrụ, yabụ kedu ka anyị ga-esi họrọ nnwale ike? Ihe ndị a na-akwado iji nnwale ike nwere usoro ibuli isi iji mezue usoro nnwale ahụ dum. Dịka egosiri n'okpuru:

Ngwọta nnwale siri ike a nwere ike imezu ule ike Rockwell/Vickers na Brinell dịka ụkpụrụ nnwale ike si dị (GB/T 231.1, GB/T 4340.1, ISO6507, ISO6508, ASTM E18, wdg), ma mezuo nnwale dị elu na ihe achọrọ maka mmepụta dị irè nke ọrụ dị arọ.

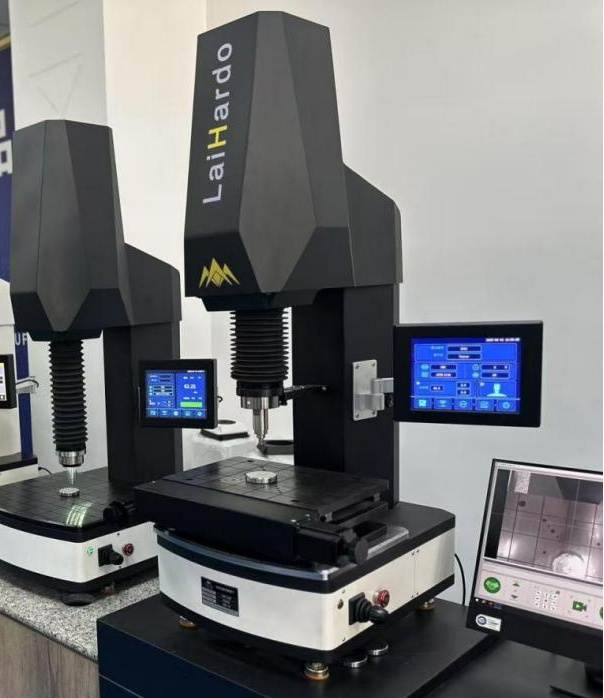

Ihe nnwale ike ibuli isi akpaka nwere oche ọrụ a kapịrị ọnụ, nke na-ebelata njehie nke skru na ibuli oche ọrụ na-akpata ruo na nha nha siri ike. Ebe ọrụ ahụ buru ibu ma nwee ike ịnabata nnukwu ọrụ ibu arọ. Nha otu bọtịnụ na-ebelata njehie na ọrụ nke onye nnwale ahụ nke ukwuu, nke dị mfe ma dịkwa ngwa ngwa.

Oge ozi: Eprel-23-2025