1) Enwere ike iji ihe nnwale ike Rockwell nwalee ike nke mgbidi paịpụ ígwè ahụ?

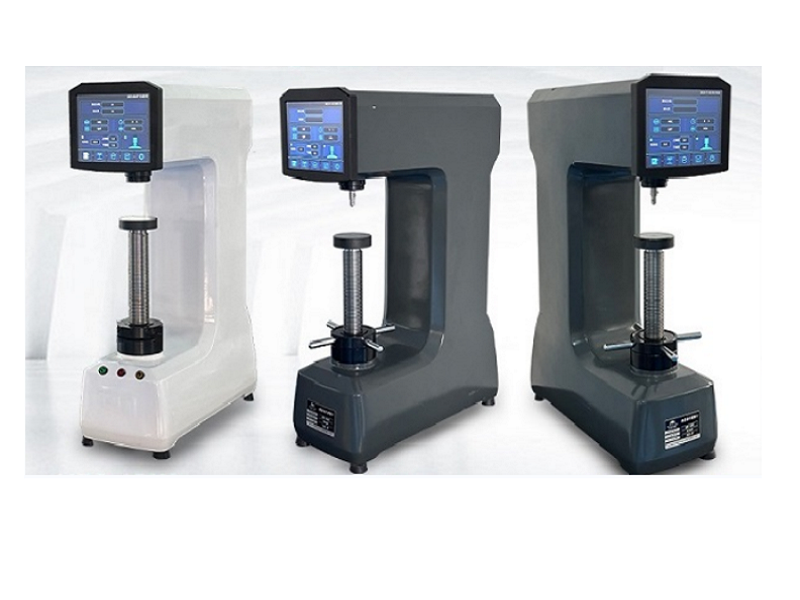

Ihe nnwale ahụ bụ paịpụ ígwè SA-213M T22 nke nwere dayameta mpụta nke 16mm na ọkpụrụkpụ mgbidi nke 1.65mm. Nsonaazụ nnwale nke nnwale ike Rockwell bụ ndị a: Mgbe ewepụsịrị oxide scale na decarburization oyi akwa n'elu ihe nlele ahụ site na iji igwe egweri, a na-etinye ihe nlele ahụ na oche ọrụ dị ka V, a na-ejikwa ihe nnwale ike Rockwell dijitalụ HRS-150S iji nwalee ike Rockwell ozugbo na elu mpụta ya na ibu nke 980.7N. Mgbe nnwale ahụ gasịrị, a pụrụ ịhụ na mgbidi paịpụ ígwè ahụ nwere obere mgbanwe, ihe si na ya pụta bụ na uru ike Rockwell a tụrụ dị oke ala, nke na-ebute nnwale na-adịghị mma.

Dịka GB/T 230.1-2018 si kwuo «Nnwale Ike nke Ihe Metallic Rockwell nke Akụkụ nke 1: Usoro Nnwale», ike Rockwell bụ 80HRBW na oke ọkpụrụkpụ nke ihe nlele kacha nta bụ 1.5mm. Oke ọkpụrụkpụ nke ihe nlele Nke 1 bụ 1.65mm, ọkpụrụkpụ nke oyi akwa decarburized bụ 0.15~0.20mm, ọkpụrụkpụ nke ihe nlele ahụ mgbe ewepụchara oyi akwa decarburized bụ 1.4~1.45mm, nke dị nso na oke ọkpụrụkpụ kacha nta nke ihe nlele ahụ akọwapụtara na GB/T 230.1-2018. N'oge nnwale ahụ, ebe ọ bụ na enweghị nkwado n'etiti ihe nlele ahụ, ọ ga-akpata obere mgbanwe (nke anya gba ọtọ nwere ike ọ gaghị ahụ), yabụ uru ike Rockwell n'ezie dị ala.

2) Otu esi ahọrọ ihe nnwale siri ike n'elu maka ọkpọkọ ígwè:

Mgbe ọtụtụ ule gbasara ike ọkpọkọ ígwè n'elu, ụlọ ọrụ anyị abịala na nkwubi okwu ndị a:

1. Mgbe a na-eme ule ike Rockwell elu ma ọ bụ ule ike Rockwell n'elu paịpụ ígwè dị gịrịgịrị, nkwado zuru oke nke mgbidi paịpụ ahụ ga-eme ka ihe nlele ahụ gbanwee ma mee ka nsonaazụ ule dị ala;

2. Ọ bụrụ na etinyere nkwado silinda n'etiti paịpụ ígwè dị gịrịgịrị, nsonaazụ nnwale ahụ ga-adị ala n'ihi na axis nke isi nrụgide na ntụziaka nke ibu ibu enweghị ike ijide n'aka na ọ ga-adị n'akụkụ elu paịpụ ígwè ahụ, enwerekwa oghere n'etiti elu mpụta nke paịpụ ígwè ahụ na nkwado silinda dabara adaba.

3. Ụzọ e si agbanwe ike Vickers a tụrụ ka ọ bụrụ ike Rockwell mgbe e tinyere ya ma kpụchaa ihe nlele paịpụ ígwè ahụ ziri ezi.

4. Mgbe ewepụsịrị ihe mkpuchi oxide na oyi akwa decarburization n'elu paịpụ ígwè ahụ ma jiri usoro nnwale ahụ mee ihe n'elu mpụta ma tinye ya n'ime ya, a na-agbanwe ike Rockwell n'elu ya ka ọ bụrụ ike Rockwell, nke ziri ezi.

Oge ozi: Jun-13-2024