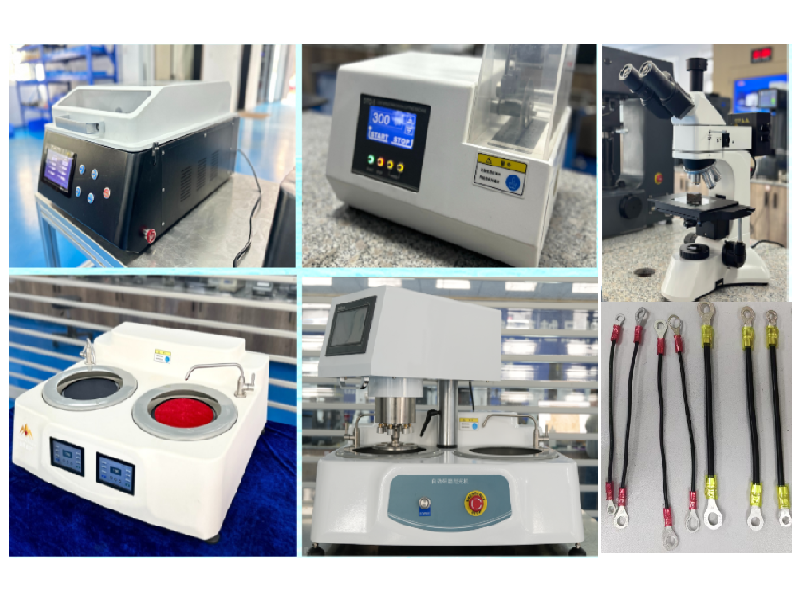

Ọkọlọtọ ahụ chọrọ ma ọdịdị nke ọdụ njikọ ahụ ruru eru. Porosity nke waya crimping njedebe na-ezo aka na oke nke mpaghara a na-anaghị emetụ aka na yankeAkụkụ njikọ dị na ọdụ crimping na mpaghara ahụ dum, nke bụ paramita dị mkpa na-emetụta nchekwa na ntụkwasị obi nke ọdụ crimping. Oke porosity ga-ebute enweghị njikọ, ịbawanye iguzogide na okpomọkụ, si otú a na-emetụta nkwụsi ike na nchekwa nke njikọ eletriki. Ya mere, achọrọ akụrụngwa nyocha metallographic ọkachamara maka nchọpụta na nyocha porosity elu. A chọrọ ịkpụ ihe nlele metallographic, igwe egweri ihe nlele metallographic na igwe polishing, na microscope metallographic iji nwalee ma kwadebe ọdụ ahụ, wee nyochaa onyonyo eserese site na ngwanrọ metallographic microscope maka nyocha akụkụ njedebe.

Usoro nkwadebe ihe nlele: A ga-eji igwe ịkpụ ihe nlereanya metallographic bee ihe nlele ahụ ma jiri igwe ịkpụ ihe nlereanya metallographic sample bee ya ma jiri ya nwalee ihe nlele ahụ - a na-atụ aro ka e jiri igwe ịkpụ ihe nlereanya ziri ezi bee ya, a ga-etinyekwa ihe osise e nwetara n'ime ihe nlele ahụ nwere ikpo okwu abụọ site na iji igwe inlay metallographic, wee jiri igwe igwekota metallographic mee ka elu nyocha ahụ dị nro ma jiri igwe igwekota metallographic mee ka ọ dị mma, wee jiri kemịkalụ mee ka ọ gbawaa ma tinye ya n'okpuru igwe microscope metallographic maka inyocha na nyocha.

Oge ozi: Maachị-28-2025